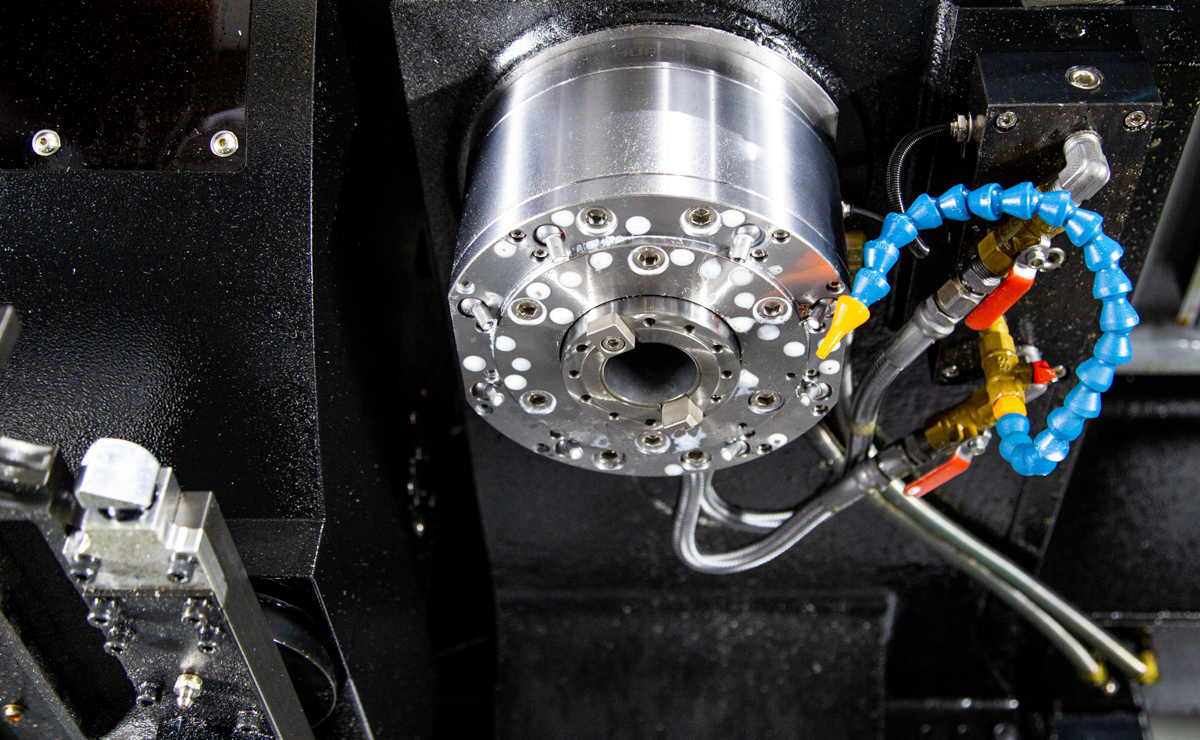

Mould Construction

A high-quality plastic part is not just created in the injection moulding machine. We lay the foundation for the perfect end product at the mould construction stage.

State-of-the-art CAD/CAM solutions (based on the scalable parametric 3D software Creo Parametric or Cimatron) enable us to optimally coordinate all work processes from the initial design to the finished product. Our quality management begins at the outset and continues through the entire production process: we map the manufacturing process of the plastic components with the help of special simulation programs. In this way, predictions can be made about the properties of the end products to be manufactured before production has begun – and errors can be avoided from the outset.

In addition to the production of tools in small or large series, we also manufacture individual prototypes. Our existing interfaces (including IGES, SET, VDA, DXF, STEP, CATIA, MEDUSA and ECAD) guarantee the safe and uncomplicated transfer of all necessary information.

Our services in mould construction:

- Conceptual design

- Mould design

- Feasibility studies

- Profitability calculations

- Product design

- Materials selection

- Quality assurance in development through design FMEA

- Test concepts integrated into the manufacturing process

- Laser repair welding

- Laser engraving