Plastic injection moulding

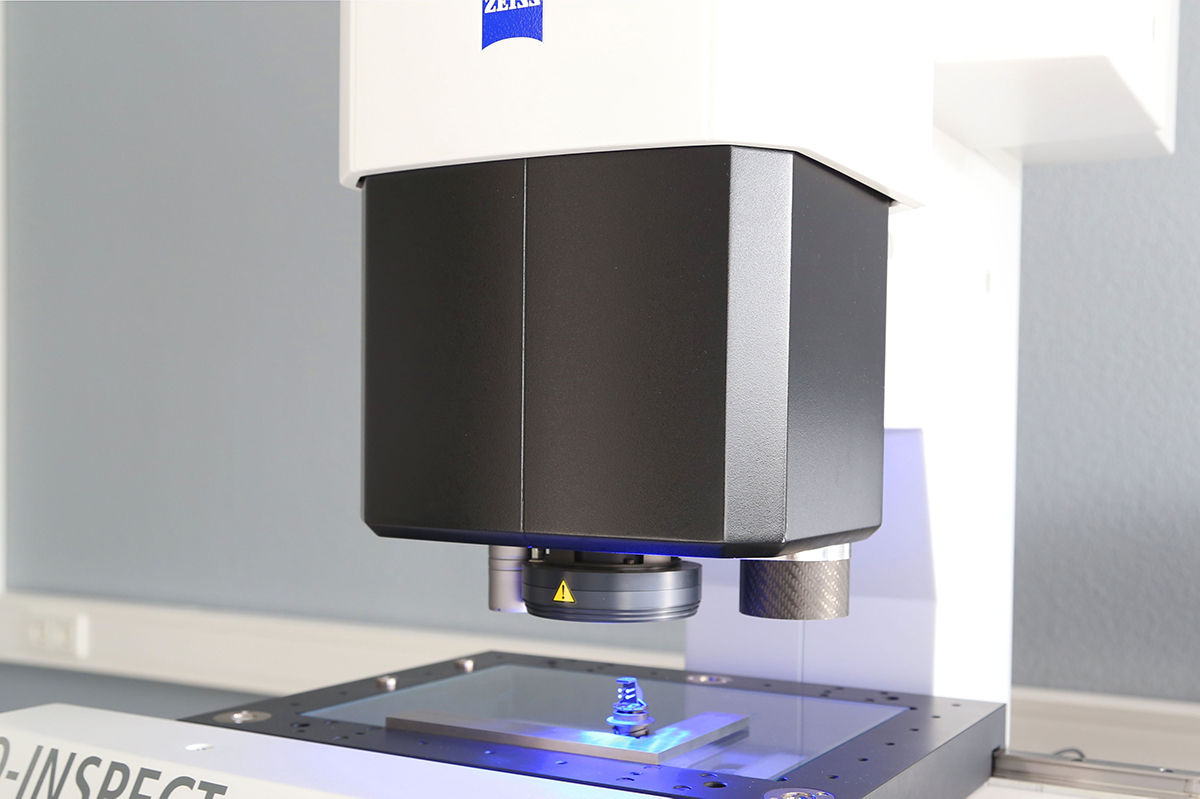

Just as important as the use of state-of-the-art injection moulding machines is the consistent monitoring of all internal work processes – this is how BOIDA produces plastic parts of the highest quality.

35 high-quality plastic injection moulding machines with clamping forces from 5 to 200 tons are available for production. These include fully electric injection moulding machines as well as turntable and multi-component systems. State-of-the-art machines and tools as well as statistical process control (SPC) procedures ensure that production runs efficiently and meets all quality requirements. Dimensional and functional controls integrated into the manufacturing processes check and document each step of production.

Ongoing process and capability analyses help us to continuously improve our work. This is how we ensure that we are delivering top performance at all times.

What we offer:

- Production of pilot, small and large series

- Continuous process and parts optimisation based on lean management methods

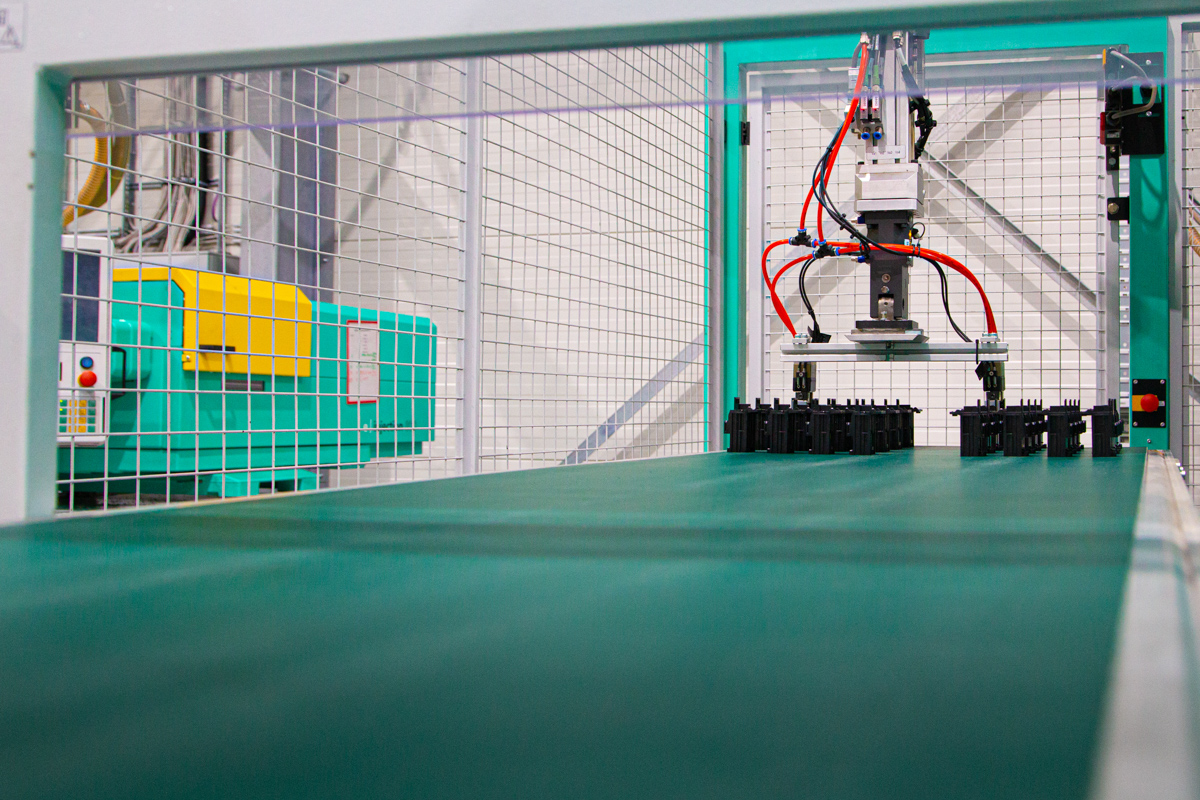

- Use of the latest removal and handling systems

- Process monitoring by means of ultra-modern integrated internal pressure sensor technology